Steel rolling mill

STEEL ROLLING MILL

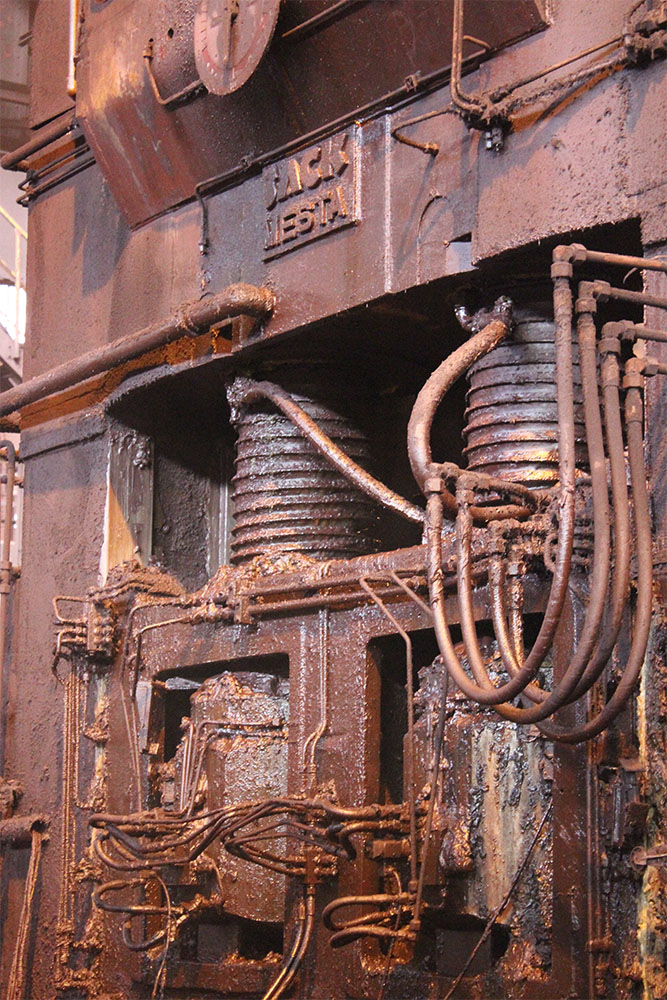

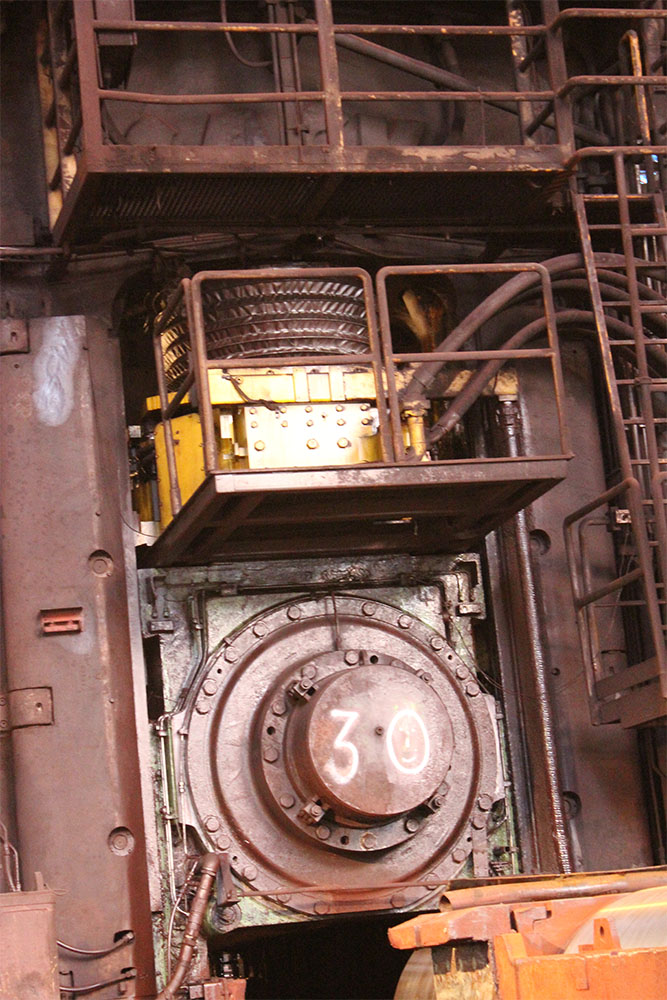

Heat, grease, dirt, extreme forces and sensitive components whose failure would result in disproportionately high costs. In the steel rolling mill, sheets weighing several tonnes are rolled down from 250 to 20 mm, for example, every minute. The final thickness of the sheets can be adjusted via the distance between the top and bottom rolls.

Bellows from August Penkert protect the adjusting cylinders and spindles reliably and for years. The last time we had to replace a bellows from a screw jack was after 35 years. The drawing as well as the manufacturing instructions for this bellows were kept in our document archive and could be examined and processed accordingly even after this long time. The new production of the bellows took only a few days.

More information about this project is available on request.